Backflow prevention is a major element within your facility. It requires an immense amount of attention to prevent contamination. Thus, ultimately protecting your consumers who dine in your restaurant. Averting contamination and protecting the customers are two fundamental reasons for requiring the installation of such devices.

Restaurant owners expect their water is safe to use when making food and serving customers. Potable water – water you can drink – becomes contaminated when it comes into contact with unsafe sources. This is why backflow testing your commercial systems is so important – they aim to keep the water we serve our customers safe.

What is Backflow?

Backflow is the reversal of the flow of water or mixture of water and other substances into the pipes of the potable water supply. Two types of backflow conditions exist; back-pressure and back-siphonage. Both have a similar meaning and cause backflow when the pressure in the public water supply exceeds the pressure in your pipes.

The city water system channels water from a treatment center straight to your faucet. This direct pathway ensures water has been treated appropriately and safe for consumption. However, changes in pressure cause water to travel backward through pipes and off its intended path – hence the name backflow. When this occurs, non-potable water from your restaurant potentially taints the public water supply with contaminants. Contaminants range from fertilizers to pesticides to human waste or soap from sinks, dishwashers, or showers.

Another term to understand is cross-connection. Cross-Connection describes any potential connection between a potable water system and any other source or system of contamination. When a cross-connection is not protected, backflow can occur.

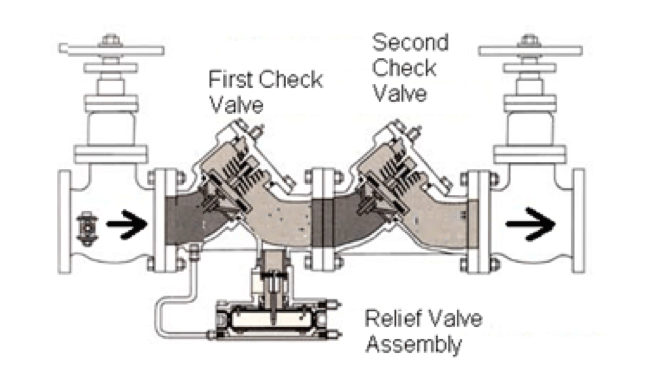

Backflow prevention devices, or cross-connection controls, can be a difficult topic to comprehend. This is mainly due to the variety of units and stipulations within each municipality and building code. However, they all function similarly and provide the same amount of protection from contamination. Backflow preventers protect against polluted or contaminated water from backing up in your facilities’ pipes and flowing into the potable water. When a building is in the initial stages of the building process or during a renovation of any kind, a professional engineer, registered architect, or licensed plumber pre-determines these devices.

Each municipality sets the standard for these devices. These standards may differ depending on the area. The restaurants within the designated areas must abide by these stipulations to remain compliant and pass each annual test and inspection. If customers drink contaminated water and become sick, you could open yourself up to legal and monetary damages.

How Do Restaurants Prevent Backflow?

As a commercial building owner or tenant, you’re responsible to prevent backflow. You can do this by using devices known as backflow preventers or cross-connection controls. You typically see backflow preventers in the following items:

- Ice makers

- Coffee machines

- Soda machines,

- Sinks,

- Dishwashers,

- Irrigation systems/sprinklers

- Fire sprinkler systems

- Other systems that uses water

The design of the preventer makes sure non-potable water cannot reach the clean water source. Think of it as a gated system. One gate allows water in from the public water supply while the other gate allows it to move through some type of exit. Both gates only allow water to travel one way while the device ensures no water will go backward to contaminate the source.

The responsibility of maintaining each backflow preventer annual falls on the restaurant owners. The owners must schedule annual testing, replacement, and repairs. Additionally, they must keep a record of the proper documentation. Many local authorities, who have jurisdiction over the water supply, require the testing and inspection is done by a certified and licensed plumber. A certified and licensed plumber has properly calibrated equipment to ensure all parts are functional.

Why Backflow Prevention Needs to be Your Priority

Understanding the need for backflow prevention and how these devices function is vital to the quality and upkeep of this mechanism. Billy Pipe is in charge of Operations at Action Wastewater. He shared his expertise and knowledge from working within the industry. Mr. Pipe made it clear that protecting the customer from contamination is the number one priority.

When asked what the importance of the backflow preventer is, he responded, “The backflow device protects the water supply from contamination. There will be occasions when there is a significant drop in pressure or is interrupted. Interruptions can occur from by a possible water main break, power outage, pipes freezing, or nearby firefighting. The drop causes the water in the pipes to be sucked back into the public drinking water system. The backflow preventer averts the potable water.” According to Pipe, each device needs to be tested by a licensed plumber according to the local jurisdiction once a year. He also states, “Each device needs to be tagged with the date of prior testing and accompany proper documentation to pass or fail inspection.”

Mark Gomolla, Director of Facilities at Red Robin Gourmet Burgers, spoke on backflow prevention and the importance of this device within his establishment. “The backflow devices are a very integral part of the restaurant. It prevents the potable water supply from possible contamination if a line breaks underground and forces contaminants into the system. Typically, we have between 1-3 backflow preventers.”

Gomolla’s establishment stays on top of the maintenance of each backflow preventer by scheduling an annual certification completed by a national provider. This certification also covers the maintenance of the valves. “We comply by sending the certification completion to the local jurisdictions when required. We also verify the tags left on the valves are up to date. Municipalities require annual testing. Some strictly enforce testing; while others do not. However, we require the records onsite in case needed for verification.”

When asked what problems he faced with this device within the restaurant, he responded, “The problems encountered have been primarily discovered during the certification. Typically the valve tends to leak after a few years and needs the gasket replaced. Another issue we’ve encountered is that the springs within the valve can get weak and the valve gets rebuilt. We’ve not had a valve fail to where it affected the restaurant.”

Professional Commercial Backflow Testing Services for Restaurants

A failing backflow device not only affects the restaurant and the consumers but the public water supply. Most jurisdictions have strict mandates to ensure these issues don’t affect the general public and potable water system. As long as restaurants remain compliant and abide by these authorities, contamination will not be a threat.

Like any piece of equipment, backflow prevention devices need maintenance to ensure they are functioning correctly. Our team of experts recommends you have each backflow prevention device inspected annually to prevent any issues.

Your partners at SLM Facilities Solutions can handle all of your backflow testing inspections to make sure you are meeting local plumbing and building codes. Our team will:

- Contact the city to obtain a backflow notice (if necessary)

- Schedule testing

- Discuss options for repairs

- Verify testing result paper sent to the city

Along with backflow testing, we serve your business by providing other services. This includes waste management and disposal, HVAC solutions, handyman, electrical, and more. Request your free facilities assessment today.